Nuclear Products

Download the full catalog

View Nuclear Products catalog

-

Low Density Silicone (GEOSEAL80)

PRODUCTS

APPLICATION

GEOSEAL80 consists of two-component low density silicone foam and is a sponge type with elasticity after curing.

It is qualified for Fire and Ventilation seals for nuclear power plant.PRODUCT PERFORMANCE

Classification Feature Fire Seal 2–3 hours (ASTM E814, UL1479) Ventilation Seal Yes Radiation Resistance 1×10⁵ Gy Surface Burning Characteristics Class ‘A’ (NFPA/IBC) STANDARD

Classification Feature Color ‘A’ : Black, ‘B’ : Off White Main Component Silicone Package A: 20kg, B: 20kg (40kg/SET) Mixing Ratio 1:1 (A&B) Expansion Rate 200 ~ 300% Pot Time 1~3 min Curing Time 24 hours Specific Gravity (after curing) 0.224 ~ 0.448 Service Temperature 400℉ (204℃) Shelf Life 12 months Limiting Oxygen Index 39 (KS M ISO 4589-2) Thermal Conductivity 0.081 W/(m·K) (ASTM C518) Volume Resistance 1.00 × 10¹⁵ Ω·cm (ASTM D257) Dielectric Breakdown Strength 3.9 kV/mm (ASTM D149) Flame Resistance Test V-0 (UL94) Halogen Free Asbestos Free PROPERTIES

Uses

Sealing opening & penetration for Tray, Conduit, Electrical Bus Duct

Installation

Store the material at room temperature for 12 hours before work(Recommendation)

Clean surface of opening & penetration

Install Dam

First Mixing : Mix the material in each package of A & B for more than 3 minutes

Second Mixing: Mix the materials of A & B together after first mixing for less than 1 minute

Pouring, then remove dam and finish surfaces after 24 hoursStorage

Avoid direct sunlight and store it in the range of 5°Cto 60°C at a well-ventilated dry place

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands

Non-reusable products after opening*The data is for information purposes only, not available for design data.

-

High Density Silicone (GEOSEAL150)

PRODUCTS

APPLICATION

GEOSEAL150 consists of two-component high density silicone.

It is qualified for Fire, Ventilation, Flood, Compartment Pressurization, and Radiation seals for nuclear power plant.PRODUCT PERFORMANCE

Classification Feature Fire Seal 2~3 hours (ASTM E814, UL1479) Flood Seal ≤0.01 gallon/min (21.7 psi) Compartment Pressurization Seal ≤0.001 cfm/ft · psid (5/10, 24/48 psid, 360°F) Ventilation Seal Yes Radiation Seal 1 × 10⁶ Gy Surface Burning Characteristics Class ‘A’ (NFPA/IBC) STANDARD

Classification Feature Color A : Grey, B : Off White Main Component Silicone Packing A: 20kg, B: 20kg (40kg/SET) Mixing Ratio 1:1 (A&B) Pot time 30 minutes Curing Time 24 hours Specific Gravity (after curing) Above 2.24 Service Temperature 400°F (204°C) Shelf life 12 months Limiting Oxygen Index 57 (KS M ISO 4589-2) Thermal conductivity 1.05 W/(m·K) (ASTM C1113) Volume Resistance 1.98 × 10¹² Ω·cm (ASTM D257) Dielectric Breakdown Strength 3.1 kV/mm (ASTM D149) Flame Resistance Test V-0 (UL94) Halogen Free Asbestos Free PROPERTIES

Uses

Sealing opening & penetration for Tray, Conduit, Electrical Bus Duct, and Pipe

Installation

Store the material at room temperature for 12 hours before work (Recommendation)

Clean surface of opening & penetration

Install Dam

First Mixing : Mix the material in each package of A & B for more than 5 minutes

Second Mixing: Mix the materials of A & B together after first mixing for more than 3 minute

Pouring, then remove dam and finish surfaces after 24 hoursStorage

Avoid direct sunlight and store it in the range of 5°Cto 60°C at a well-ventilated dry place

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands

Non-reusable products after opening.*The data is for information purposes only, not available for design data.

-

High Density Grout (GEOGROUT150)

PRODUCTS

APPLICATION

GEOGROUT150 is a pre-mixed high density non-shrink grout that can be used mixing with only water in the field.

It is qualified for Fire, Ventilation, Flood, Compartment Pressurization, and Radiation seals for nuclear power plant.PRODUCT PERFORMANCE

Classification Feature Fire Seal 2–3 hours (ASTM E814, UL1479) Flood Seal ≤ 0.01 gallon/min (21.7 psi) Compartment Pressurization Seal ≤ 0.001 cfm/ft · psid (5/10, 24/48 psid, 360°F) Ventilation Seal Yes Radiation Seal 1 × 10⁶ Gy Surface Burning Characteristics Class ‘A’ (NFPA/IBC) STANDARD

Classification Feature Color Indian Red Main Component Cement Packing 25kg/bag Mixing ratio with water 4–4.6ℓ/bag Mixing Temperature range 20±3℃ Liquidity 10 ~ 30 sec (ASTM C939) Bleeding No visible (ASTM C940) Pot time 30 min Curing Time 7 days Expansion / Shrinkage rate below 0.3% / None Shrinkage (ASTM C1090) Specific Gravity (After curing) above 2.24 Compressive Strength above 4,000 psi (28 days) Service Temperature 200℉ (93℃) Shelf life Valid for LOT period Thermal conductivity 0.92 W/(m·K) (ASTM C1113) Halogen Free Asbestos Free PROPERTIES

Uses

Sealing opening & penetration for Tray, Conduit and pipe

Installation

Clean the opening & penetration surfaces Install Dam

Mix the product with water (4~4.6l/bag) for more than 2 min±10sec

Pouring, Remove Dam after 1 to 5 curing days and surface cleaningStorage

Avoid direct sunlight and store it in the range of 5°Cto 60°C at a well-ventilated dry place

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands

Non-reusable products after opening.*The data is for information purposes only, not available for design data.

-

Non-Shrink Grout (GEOGROUT120)

PRODUCTS

APPLICATION

GEOGROUT120 is a pre-mixed non-shrink grout that can be used mixing with only water in the field.

It is qualified for Fire, Ventilation seals for nuclear power plant.PRODUCT PERFORMANCE

Classification Feature Fire Seal 3 hours (ASTM E814) Ventilation Seal Yes Surface Burning Characteristics Class ‘A’ (NFPA/IBC) STANDARD

Classification Feature Color Grey Main Component Cement Packing 25kg / bag Mixing ratio with water 4.0 ~ 4.6ℓ / bag Mixing Temperature range 20±5℃ Liquidity 10 ~ 30 sec (ASTM C939) Bleeding No visible (ASTM C940) Pot time 30 min Curing Time 7 days Expansion / Shrinkage rate below 0.3% / None Shrinkage (ASTM C1090) Specific Gravity (After curing) above 2.15 Compressive Strength above 6,500psi (28days) Service Temperature 300°F (149°C) Shelf life Valid for LOT period Halogen Satisfy for Reg. 1.36 (ASTM C795) Asbestos Free Chloride below 300ppm PROPERTIES

Uses

Sealing opening for Conduit besides machinery foundation’s substructure that receives high impact

Installation

Clean the opening & penetration surfaces Install Dam

Mix the product with water (4.0~4.6l/bag) for 3~5 min

Pouring, Remove Dam after 1 to 5 curing days and surface cleaningStorage

Store above 5°C and below 60°C in a closed container and in cool, dry location

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands

Non-reusable products after opening*The data is for information purposes only, not available for design data.

-

Boot Fabric (GEOSEAL730)

PRODUCTS

APPLICATION

GEOSEAL730 (Boot fabric) consists of reinforced glass fiber with silicone rubber and can be used for

movement requirement of mechanical penetration items.

It is qualified for Ventilation, Flood, Radiation, and Compartment Pressurization seals for nuclear power plant.GEOSEAL730 (Boot fabric) consists of reinforced glass fiber with silicone rubber and can be used for movement requirement of mechanical penetration items.

It is qualified for Ventilation, Flood, Radiation, and Compartment Pressurization seals for nuclear power plant.PRODUCT PERFORMANCE

Classification Feature Flood Seal ≤0.01 gallon/min (21.7 psi) Compartment Pressurization Seal ≤0.001 cfm/ft · psid (5/10, 24/48 psid, 360°F) Ventilation Seal Yes Radiation Resistance 1×10⁶ Gy Surface Burning Characteristics Class ‘A’ (NFPA/IBC) STANDARD

Classification Feature Color Dark Blue Main Component Reinforced glass fiber and Silicone Thickness 0.031″ (0.79 mm) Packing 0.9 m × 30 m / roll (27 m²) Service Temperature 400°F (204°C) Shelf life 60 months Dielectric Breakdown Strength 9.4 kV/mm (ASTM D149) Thermal Conductivity 0.171 W/(m·K) (ASTM C518) Halogen Free Asbestos Free PROPERTIES

Uses

Sealing opening with movement for Piping, Duct.

Installation

Clean and dry the penetration surfaces.

Design and cut the boot. Fix the boot with steel plate, screw, clamp, sealant.

*In case of nuclear power plant, inner sleeve, ceramic fiber, and high density grout are required as per detailed installation drawing.Storage

Avoid direct sunlight and store it in the range of 5℃ to 60℃ at a well-ventilated dry place

Caution

Be careful not to be torn the product

*The data is for information purposes only, not available for design data.

-

RTV Foam Pad (Joint Filler) (GEOSEAL80)

PRODUCTS

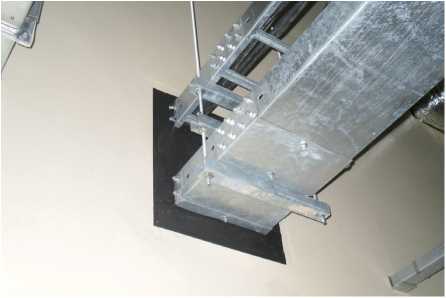

APPLICATION

GEOSEAL80 RTV Foam Pad is a pre-expanded low density silicone like sponge pad.

It can be used for sealing in high-rise buildings, power plants, chemical plants and oil refineries as a fire resistance penetration sealing system.PRODUCT PERFORMANCE

Classification Feature Fire Resistance 2 hours (Vertical and Horizontal) Regulation by MOLIT of Korea government

KS F ISO 10295-1,

KS F 2257-1Radiation Resistance 1×10⁶ Gy Surface Burning Characteristics Class ‘A’ (NFPA/IBC) STANDARD

Classification Feature Color BLACK Size 500W X 500H X 30, 50, 75T Main Component Silicone Specific Gravity 0.224~0.448 Service Temperature 400°F (204°C) Limiting Oxygen Index 39 (KS M ISO 4589-2) Thermal Conductivity 0.081 W/(m·K) (ASTM C518) Volume Resistance 1.00×10¹⁵ Ω·cm (ASTM D257) Dielectric Breakdown Strength 3.9 kV/mm (ASTM D149) Flame Resistance Test V-0 (UL94) Halogen Free Asbestos Free PROPERTIES

Uses

Sealing opening & penetration of Tray.

Installation

Clean the opening & penetration surface. Cut Foam Pad to fit the opening size and install.

Caulk GEOSEAL100 to all of joints. Fix insulation material according to the specified length on a cable trayStorage

Avoid direct sunlight and store it in the range of 5°C to 60°C at a well-ventilated dry place

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands*The data is for information purposes only, not available for design data.

-

Fire-Proof Sealant (GEOSEAL100)

PRODUCTS

APPLICATION

GEOSEAL100 is one-component fire stop sealant that can be used in combination with GOESEAL80 RTV FOAM PAD for general fireproof structure.

In addition, it is qualified for Fire and Ventilation seals for nuclear power plantPRODUCT PERFORMANCE

Classification Feature Fire Seal 3 hours (ASTM E814) Ventilation Seal Yes Radiation Resistance 1×10⁶ Gy STANDARD

Classification Feature Color Black Main Component Silicone Packing 300ml/ctg Service Temperature 200°F (93°C) Shelf life 1 year Curing time Surface curing: within 15min

Full curing: 7~15daysThermal Conductivity 0.26W/(m·K) (ASTM C518) Slump Width (0), Height (0) Specific Gravity 1.45 ~ 1.52 Halogen Free Asbestos Free PROPERTIES

Uses

Joint sealing for GEOSEAL80 RTV Foam Pad for cable tray.

Fire and Ventilation sealing for penetration of conduit in nuclear power plantInstallation

Clean and dry the penetration surface. Recommend masking tape working.

Remove masking tape after sealing and tooling working.

In case of nuclear power plant, sealing inside of conduits as per detailed installation drawing.Storage

Avoid direct sunlight and store it in the range of 5°C to 60°C at a well-ventilated dry place

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands

Non-reusable products after opening*The data is for information purposes only, not available for design data.