Low Density Silicone (GEOSEAL80)

PRODUCTS

APPLICATION

GEOSEAL80 consists of two-component low density silicone foam and is a sponge type with elasticity after curing.

It is qualified for Fire and Ventilation seals for nuclear power plant.

PRODUCT PERFORMANCE

| Classification | Feature |

|---|---|

| Fire Seal | 2–3 hours (ASTM E814, UL1479) |

| Ventilation Seal | Yes |

| Radiation Resistance | 1×10⁵ Gy |

| Surface Burning Characteristics | Class ‘A’ (NFPA/IBC) |

STANDARD

| Classification | Feature |

|---|---|

| Color | ‘A’ : Black, ‘B’ : Off White |

| Main Component | Silicone |

| Package | A: 20kg, B: 20kg (40kg/SET) |

| Mixing Ratio | 1:1 (A&B) |

| Expansion Rate | 200 ~ 300% |

| Pot Time | 1~3 min |

| Curing Time | 24 hours |

| Specific Gravity (after curing) | 0.224 ~ 0.448 |

| Service Temperature | 400℉ (204℃) |

| Shelf Life | 12 months |

| Limiting Oxygen Index | 39 (KS M ISO 4589-2) |

| Thermal Conductivity | 0.081 W/(m·K) (ASTM C518) |

| Volume Resistance | 1.00 × 10¹⁵ Ω·cm (ASTM D257) |

| Dielectric Breakdown Strength | 3.9 kV/mm (ASTM D149) |

| Flame Resistance Test | V-0 (UL94) |

| Halogen | Free |

| Asbestos | Free |

PROPERTIES

Uses

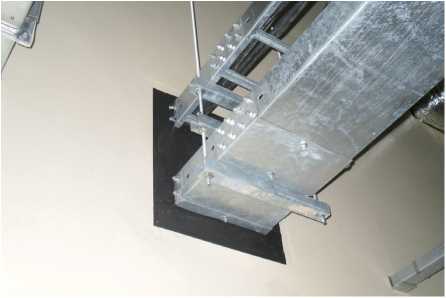

Sealing opening & penetration for Tray, Conduit, Electrical Bus Duct

Installation

Store the material at room temperature for 12 hours before work(Recommendation)

Clean surface of opening & penetration

Install Dam

First Mixing : Mix the material in each package of A & B for more than 3 minutes

Second Mixing: Mix the materials of A & B together after first mixing for less than 1 minute

Pouring, then remove dam and finish surfaces after 24 hours

Storage

Avoid direct sunlight and store it in the range of 5°Cto 60°C at a well-ventilated dry place

Caution

If it gets into your eyes, wash it with water immediately

Be careful not to touch children’s hands

Non-reusable products after opening

*The data is for information purposes only, not available for design data.