|

|

|

|

|

| The hydranut system is a tensioning system that is a direct retrofit for any existing tensioning system currently used on the Reactor Vessel |

| The system itself is of a modular design tensioner and integrated mechanical lock ring to tetain load generated through the use of hydraulice. |

| Hydranuts allow for 100% tensioning of all studs simultaneously, but also offer the flexibility of tensioning individual studs without compromising previously tensioned ones |

|

|

|

|

|

|

|

|

|

|

|

| HYDRANUT |

|

PUMP |

|

HOSE & COUPLER |

|

HYDRANUT SYSTEM |

|

|

|

|

|

|

|

|

|

|

|

|

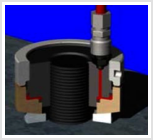

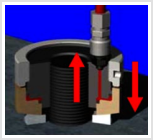

| Place hydranut in the bolt or stud |

|

Connect the hydraulic hose to all hydranuts |

|

Operate hydraulic pump and pressurize to Pre-determinded pressure |

|

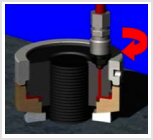

Rotate the lock ring depressuruze the hydranlic system |

|

|

|

|

| Typical hydranut applications |

| Application |

Time achieved |

| Steam safety valves |

3 minutes per flange |

| Heat exchangers |

20 minutes for closure |

| Reactor coolant pumps |

60 minutes for main flange |

| Steam generators |

18 minutes per manway |

| Reactor vessels |

90 minutes for main flange |

| Turbine valves |

15 minutes |

| Pressurizer manways |

20 minutes |

|

|

|

|

| Absolutely achieves "ALARA" |

| - Reduces # of people involved |

| - Fastest possible way to close joint |

| - Keeps operators away from highest dose areas in short time |

|

| Maximizes "joint integrity" by applying 100% load simultaneously to all stud / bolts |

| Reduces risk of injury by avoiding the use of heavy equipment and dangerous processes |

| Predictable timing for activity allows for accurate "critical path" planning |

| Reduced risk of "galling" reduces cost of stocking, and expediting materials. |

|

|